Imagine yourself in the grill with your golf buddies after the day’s play, drinks in hand reflecting upon your round.

“Man, my new forged irons were great! I had six-iron to 13 – that grain structure felt great, and then an eight-iron on 18 for all the scats – sounded terrific and loved the new grip – 5 stars!”

And your best buddy across the table answers with,

“Cool, but did you see the ball flight with my new cast irons on the 12th and the back-spin on my wedge on 16 – sucked it right back into the fringe – probably 4-stars!”

Is that really how you measure your round? Are those meaningful ways to evaluate new clubs? How then do you account for sound and feel and ball flight and spin on your scorecard?

Does the scorecard care? Should you care?

We golfers want many different things from of our games (and our equipment). It can be entirely about the score, or who won the bets, or the camaraderie, steadily improving, getting outdoors, or just the satisfaction of hitting a few good shots. What we truly seek from our golf should drive our equipment choices.

Let’s peel back the onion a little and see what has really been going on in contemporary golf equipment.

Marketing Hyperbole, Techno-Babble, Misdirection, and Outright BS

With the golf club technology advances claimed by the OEMs during the last 20 years, we should all be hitting 400-yard drives and shooting 54’s by now.

My favorite techno-babble marketing claim was made during the early 1980’s for the Palmer golf ball with an innovative steel center saying, “Our ball will go as far as you can hit it!” – golf OEMs do enjoy a little humor sometimes. And leading in the nostalgia category, the marketing for the Hogan EDGE forged cavity back irons introduction (from the late 80’s) included Mr. Hogan’s quote (and video) about the “feel” of a great forged iron going up the shaft and “right into your heart.”

As an aside, I actually worked for Mr. Hogan as his Director of R&D (unlike some others who claimed they did, but did not) and have a heart-felt respect for him – he was probably the greatest player ever.

Arguments about grain structure and voids abound, but if forged clubs actually performed better, every tour player would use nothing else today, and robot and player testing would prove it conclusively, and the premier golf club companies would make nothing else. So, where is the evidence? Much of the forged mystique is also based upon misdirection, techno-babble, and nostalgia – not data! Yet forged clubs may still be the right choice for some of us.

And likewise with investment castings – if they were demonstrably superior to forgings, why would anyone ever play forgings? Alternatively, if investment casting indeed produced “inferior” performance golf club heads, PING would have never sold golf club one. Yet PING established their brand from performance inferences only (with a great Pro Tours program) – and not aesthetics or “feel”.

The two current sales leaders in the wedges category (Vokey and Cleveland) , where FEEL is supposedly paramount, are both INVESTMENT CAST club heads.

The truth is that there is widespread Marketing Misdirection from the OEMs – i.e. higher ball spin on wedges (what you need is enough spin for control), sound and feel on irons (where do I put that on my score card?), longer drivers (for whom?), and “Tour” usage (those guys can hit anything and play whatever they are PAID to play).

What these OEMs should be selling us instead is control, consistency, predictability, forgiveness, accuracy, versatility, and adjustability (with good configuration options for fitting). These are the elements of great golf club design, but they are not nearly as sexy as the claims of prodigious driver distances, or wedges that suck the ball back with excessive spin.

To be fair, though, the golf media has lived a daily conflict of interest with regard to reporting on OEM product offerings – trying to balance serving the interests of their readers against their own financial interests for larger advertising revenues. Would you believe that the OEMs with the largest advertising budgets might have gotten slightly more favorable product reviews or been included in the equipment reviews more regularly?

Cutting Through the BS

It’s time then to dispel some of the myths about golf clubs, because, despite the marketing hyperbole to the contrary, EITHER forged or cast (or a multi-material combo) might be the correct answer for you as a player.

Nicklaus, Palmer, Player, Snead, Hogan, and Byron Nelson all played very well decades ago with low tech forged blades and persimmon woods, so they must have worked OK once upon a time. And Nelson is credited with having quite humorously observed that he thought the greatest advance in golf equipment during his era was the lawn mower – which was in fact probably correct for his time.

But much has been happening in golf club design since about 1980, and a new threshold of R&D sophistication has even become possible in the last 10-20 years with the creation of computer simulations, a better robot (the Parente Golf Labs design), and now good launch monitors and simulators to measure the results of both robot and player testing with great precision and consistency.

These are the essential cornerstones of good R&D now and into the future, but some OEMs still lack the right personnel to do this and are struggling with it, or worse they simply do not know how to do it!

Thirty years ago the Chief of Design for most OEMs was the company employee with the lowest handicap (or the guy who shouted the loudest during the design meetings), but these dinosaurs of design have been steadily replaced with Ph.D.s and engineers who use computer modeling, robots, skilled player test panels, good data gathering equipment, and real R&D test disciplines.

Good ideas and personalities are just not enough any longer for golf product leadership.

MY PERSPECTIVE OF EQUIPMENT REVIEWS

Media test panels, even when they are Ph.D.s (but from outside the golf industry), giving qualitative stars to one brand or golf club versus another give us little to go on as golfer-consumers. And written or video golf club review commentaries from teachers, players, and “garage tinkerers” on the internet really lack any foundation for making good design and performance judgments – though many of them are quite assertive and authoritative – some even entertaining.

Yet, the golf consumer is still spending thousands of dollars on golf equipment based upon marketing misdirection and qualitative product reviews.

As a golf industry R&D guy for more than 30 years now, I like where the MyGolfSpy guys are headed with objective, quantitative testing that uses real test controls and disciplines. (That is why I am pleased to write for them.) Theirs is meaningful information that mirrors what the OEM R&D groups should be doing during their final testing for new products to confirm they have them right. And it offers great value for the confused consumer who deserves better from the golf media!

Perhaps a look backward will help add perspective to the differences in current golf club designs.

History Lesson: Forged Irons

The first irons were indeed “hand-forged” from iron – by blacksmiths (in between repairing wagon wheels), and then by golf club makers who were really part-time specialty blacksmiths.

Many early irons designs were quite interesting – tiny-headed “rut irons” for playing shots from wagon wheel ruts and slotted-face “water irons” for playing shots from water, just to name a couple. Perimeter weighted irons are in fact a 100 year-old idea. The archives of the patent office and our golf history are rich with many amazing ideas. We are literally talking about 500 years of golf nuts (like ourselves) contemplating how to improve their games with better golf club designs.

From the inception of golf until the early 1900’s, sets of clubs were mostly (or entirely) long-nosed woods. “Hand-Forged” irons were few. While shaping metals with early hand-forged processes did limit the design possibilities for metal irons, the development of irons was more effectively stymied by the poor durability of the early golf balls.

Irons had to wait for a better ball to come along.

Perimeter weighted, cavity-back forged irons were not even offered commercially until as recently as the late 1980’s – and still only when the forging producers were forced to do so by the economic reality of declining forged irons sales, as investment cast offerings from the OEMs began to gain broader consumer acceptance.

Contemporary FORGED Irons Manufacturing Processes

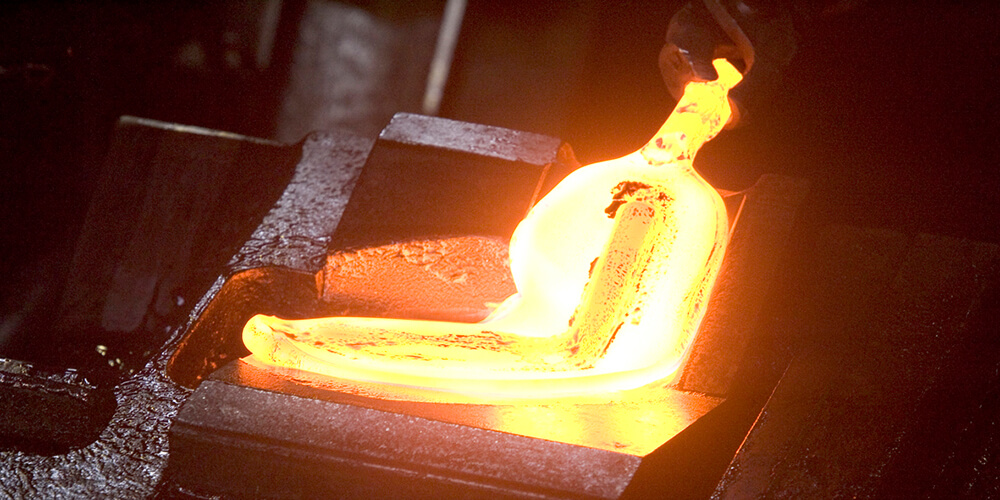

Forged golf club manufacturing processes are no longer “hand forged” for nearly a century now. They are instead “drop-forged” with huge drop forge “hammers” – so large they literally shake the factory floor with every forging hammer blow. A red hot cylindrical bar of carbon steel is “drop-forged” through 3 to 5 progressive dies. With each blow, the bar gradually morphs into a very rough golf club shape (that still requires extensive work before becoming a golf club head). You can see good examples of this drop forging process on the Internet.

Until very recently, these RAW forgings still barely resembled a golf club head. They were L-shaped pieces of scaly steel with the longer leg of the “L” flattened and angled to become the clubface and the shorter leg left in a cylindrical shape to become the hosel. There was much work then yet to be done to manufacture a conventional forged iron, with 50 to 60 grams of steel (20%+ of the total weight) commonly removed during the shaping and finishing manufacturing processes.

The finishing processes for forged irons production includes nickel-chrome plating, which is now practically unavailable in the US (due to EPA restrictions), and the manufacturing personnel with the skills essential for shaping and finishing golf club heads have pretty much disappeared from the US as well (labor unions and offshore competition). There was also the very large tooling development cost (for forging and stamping dies) associated with making forged clubs that was 5-10 times more expensive than the cost of making molds for a set of investment cast clubs.

Next Generation Forgings

Where the Japanese have recently led the golf business with high quality forged club heads and steels, they now have significant competition appearing. And, despite the marketing hyperbole suggesting otherwise, there are in fact NO golf clubs made today like Japanese swords with hand-forged, thin layered, and folded steels.

New “5-Step Precision Forging” processes are emerging that originated in the Chinese defense aviation industry. They produce the “near-net” precision shaping of investment casting but with the benefits of softer forged materials. A near final form forging is achieved using 1-2 extra drop forge hammer blows, thereby requiring much less grinding and polishing to achieve a final shape. This process requires much less work through manufacturing, provides far more consistency, and better replicates what the designer intended. And, the tooling development costs for these new forged sources are far more reasonable than older forged tooling costs used to be.

Advocates of more expensively made forged clubs and processes suggest to you inferences of price equated with performance, greater attention to detail, precision, quality, craftsmanship, and manufacturing process demands and skill. A few of these suggestions might be valid in some brand-to-brand comparisons, but is there real value-added from a critical performance attributes standpoint?

History Lessong: Investment Cast Irons

The U.S. recession of the mid 1970’s, the end of the Vietnam war, and the accompanying downturn in the U.S. aerospace industry opened the door to investment casting technology and the requisite manufacturing capacity for producing golf club heads, as the aerospace industry looked for other ways to sell their investment casting expertise and excess capacity.

After all, how difficult could making golf clubs be?

Actually, golf clubs turned out to be far more challenging than making aerospace and defense parts.

Making golf club heads by investment casting also quite importantly erased one of the essential barriers to the emergence of new brands and ideas for golf – the very large capital investment required for factories and tooling and the challenge of putting together a skilled work force to make golf clubs.

Golf club production prior to the 1980’s was dominated by a hand full of large brands with factories and skilled workforces capable of manufacturing forged irons and persimmon woods – Wilson, MacGregor, Spalding, Palmer, Hogan, et al. (It’s interesting how most of those companies are basically gone now – there is probably a lesson in that somewhere.)

Investment cast irons and metal woods were to change everything – Innovation was about to explode!

Investment casting in the early 1980’s was done with VERY hard metals (lots of 17-4 stainless) that sounded harsh and produced bone-jarring vibration on off-center impact, but the better cast designs still captured the attention of the golfer-consumer, as they were indeed superior performers to forged blades. They were also far easier for the OEMs to manufacture with only some light assembly required.

Investment casting technologies and metallurgy have evolved enormously over the last 30 years with new metals that are softer but sufficiently durable, and casting allows much greater design versatility for enhanced performance.

The early cast manufacturers were pretty much limited to PING (already investment casting aerospace parts when they entered golf) and those who made cheap clubs or lacked the manufacturing process capabilities to make serious forged golf clubs. (Note my sarcasm here). Investment casting was scoffed at in its early years as being synonymous with low quality, but what if PING was actually leading the way into new technology?

Multi-Material Clubs and Evolving Design

The R&D guys kept thinking.

Now, Multi-Material club heads are becoming the new standard with some forged parts and other investment cast steel parts that are combined to provide the best of both worlds. Other additional materials are even added for vibration dampening and final weight adjustment is done with high-density tungsten pieces inserted to increase MOI and move the CG positions significantly. These multi-material combination club heads now commonly include forged steel + investment cast or CNC milled steel (or exotic alloys) + high-density tungsten weighting inserts + urethane vibration dampening molded pieces + stamped aluminum graphics badges, totaling 5 or more materials and parts in a single club head. These are generally exceptional golf clubs, and they represent the direction of the future.

We are now seeing sets of irons come to the market place now that also include very sophisticated transitions in design and material combinations. These transition from hybrids for the long irons, to multi-material playability middle irons, and finally evolve into blade-style (or near blade) short irons.

MANUFACTURING AND R&D

Forging offers better grain structure with fewer voids? Perhaps, but how does that grain structure with fewer voids really translate into better performance anyway? Where is the cause and effect relationship? Where is the test data?

The truth is that the execution of the shot is pretty much over by the time you feel it. Granted, the need for learning curve feedback is essential, but castings will provide that also.

Investment Casting permits much greater latitude in design, and it provides greater manufacturing precision and consistency with less process control and expense – it is superior in most respects to forging. Casting absolutely delivers a consistently better representation of what the designer intended, and it affords less opportunity during the cast club head manufacturing process for alteration of the design from that intended by the designer – unlike the forged process.

Beyond that, properly “matched” sets of irons are more readily achieved with investment cast heads, as they exhibit less variation in their finished forms for generally more consistent manufacturing (when they are assembled in equivalent manufacturing operations).

Which leads us naturally into a next unanswered question of manufacturing execution – which applies to both forged or cast clubs. Delivering extraordinary golf club design to the golfer-consumer is ultimately limited by how well the golf clubs you buy have been manufactured. You should NOT assume all OEMs are equal in manufacturing excellence – they are NOT!

AND, you should also NOT assume that the R&D capabilities and design understandings of the various OEM brands are all equivalent – they are NOT! Some OEM golf club R&D groups are exceptionally capable – while others have not even cracked the code on some of the golf club design basics! And most OEMs are still working on the development of a proper set of design progressions from club to club in sets (or at least they SHOULD be).

Despite the development of exotic vibration dampening, acoustics, and weight distribution systems, there is still not even widely accepted consensus among OEMs on even the design basics of CG locations (evidence the MyGolfSpy testing of drivers with divergent CG locations from a few months ago), offset schemes, sole design, bounce, etc. There is still much that remains unknown from an R&D standpoint to provide the golfer-consumer with better designed, properly matched, superbly manufactured, and properly fitted golf clubs.

AND YOU MUST PAY ATTENTION TO THE SHAFT TOO! Even a mediocre club design configured with an excellent shaft that fits your game properly will usually perform satisfactorily for you, but the converse is NOT true! A great club head design with a poorly designed, manufactured, or fitted shaft can be completely unhittable! The shaft component in many cases (and how well it matches your game and swing) can be FAR more important than the particular club head design. Better players should focus even more heavily on matching the right shaft with a decent club head design and then being properly fitted.

SO HOW MUCH DOES CAST OR FORGED MATTER?

Tour players use cast playability clubs and forged blades alike, but they keep it on the center of the clubface with great regularity. For many better players (probably no worse than single-digit handicap), a good forged iron will provide them sufficient playability. Higher handicappers (and better players too) will benefit from the improved accuracy and modern technology of investment cast clubs – producing lower scores with their greater design latitude when the inevitable human error is introduced.

Playability clubs are generally good medicine for the eternal optimism that keeps us playing golf. But, let’s keep them in perspective. The differences in shot dispersion performance (accuracy) for off-center hits between a good contemporary forged blade design and a high MOI multi-material club are similar to the contrast in sizes between your den and your smallest bedroom.

This, of course, also greatly depends upon how far off-center the measured impacts occur, but the performance differences are maybe not as much as you might think. These tighter shot dispersion patterns will, however, translate into more greens hit and shorter putts and ultimately lower scores at the golf course.

So, how consistently you can keep impact near the center of the clubface matters greatly for influencing what your club head design choices should be.

So, What Should Your Take-Away Be From All of This?

There is no denying that for many of us golf is still an emotional experience on many levels. So, the looks and sounds and feel matter. It may not be about medal play scores for some of us at all!

How you FEEL ABOUT your clubs really does matter. You need to like seeing what you place behind the ball, if you are to make a confident and affirmative swing at the ball – and not tentatively steer the club through impact. So, aesthetics, profile shapes, finishes, offset schemes, weight and balance, ALL matter greatly to us golfers in the final analysis.

The truth is either forged or cast clubs can be right for you, and now you can even have a little of both in one club with the multi-material combinations. The good news is you have a lot of choices, just don’t let yourself be seduced by misleading marketing.

Focus then on what appeals to you and YOUR legitimate needs for performance. Be realistic about your needs vs. your desires to look like a “player”. The stigmas once associated with being a “hack player” if you play cast clubs are far behind us – the cliché that “real players hit forged blades” is just no longer true.

Get What YOU Like, have them properly fitted, and put the equipment question behind you for a while.

See, I told you it was a little complicated . . .

lordsangone

6 years ago

its been almost 30 yrs since i bought my mizuno forged blades. so i thought id check how irons look these days and esp how blades are fairing compared to the newer tech. ever since i began golf, the words cavity-back were not very optimistic terms to me. imagine a cavity-back wedge? how about a cavity back driver? i know that the topic is about forged vs cast irons but lets face it, cavity-backs are synonymous with cast irons although they do make forged cavity-backs but thats a whole other topic. i started to play golf in the early 90’s and i peeped at tiger woods irons. mizuno mp14’s and he wasnt even sponsored by them, yet. so i started off with forged blades and switched to cast irons and than back to forged. mp14, mp21, mp29, mp100 and the transitional forged blades. my best scores and maximum efficiency came from forged blade play. its amazing to see how many friends and people in general throughout the years have spent thousands of dollars buying new irons and woods. ive dabbled with many but only ever bought one set of irons, the mp14’s that tiger and nick faldo used. til this day my old assd clubs still look newer than the freshly bought sets my friends and family keep buying every other year. theres something about those flashy nickel plated blades, simple and shiny design yet everlasting. i would love to have solid forged woods but that would be illegal. back to what i was saying about cavity-backed clubs, your missing a chunk of steel right in the middle to make the sweet spot bigger cause of the weight is distributed outer perimeter. an off center hit can feel the same as a center hit with casted irons. so feedback and feel can be deceptive. people forget that it may be more forgiving but its at a price. a blade is slimmer and usually with lesser bounce as well. there is no weight distribution outwards because its solid steel. it forces you to swing the club right and the solid steel allows you to get that instant feedback. mishits are more coherent with blades. you can be more precise about what you did wrong and more importantly what you did right. there is nothing more satisfying feeling than a dead center hit or slightly off center. forged blades are just a more immersive and truer gameplay. we cant rely on gimmicks and trinkets for a solid golf game. in the end casted cavity-backs are just that. a tweek design for the lesser tweeking player who rather be decieved by off center hits than to face the vibrations of an off center hit of a forged iron. its just solid unlike casted irons. satisfaction, confidence, positive thinking, feel, feedback, etc are soo important in your mental game and we all know its 90 percent mental, right?